>AI Generated Virtual Industrial Machines

A digital twin platform that uses AI to automatically generate Modelica simulation models from historical machine data, making testing and maintenance of industrial machines more cost-effective.

>Problem & Solution

Problem

Industrial machines require regular testing and maintenance, which is costly and expensive. Digital twins offer a more cost-effective alternative, but creating these digital twins traditionally requires significant manual labor using Modelica simulations. The challenge was to streamline and automate this process to make digital twins more accessible and practical for industrial applications.

Solution

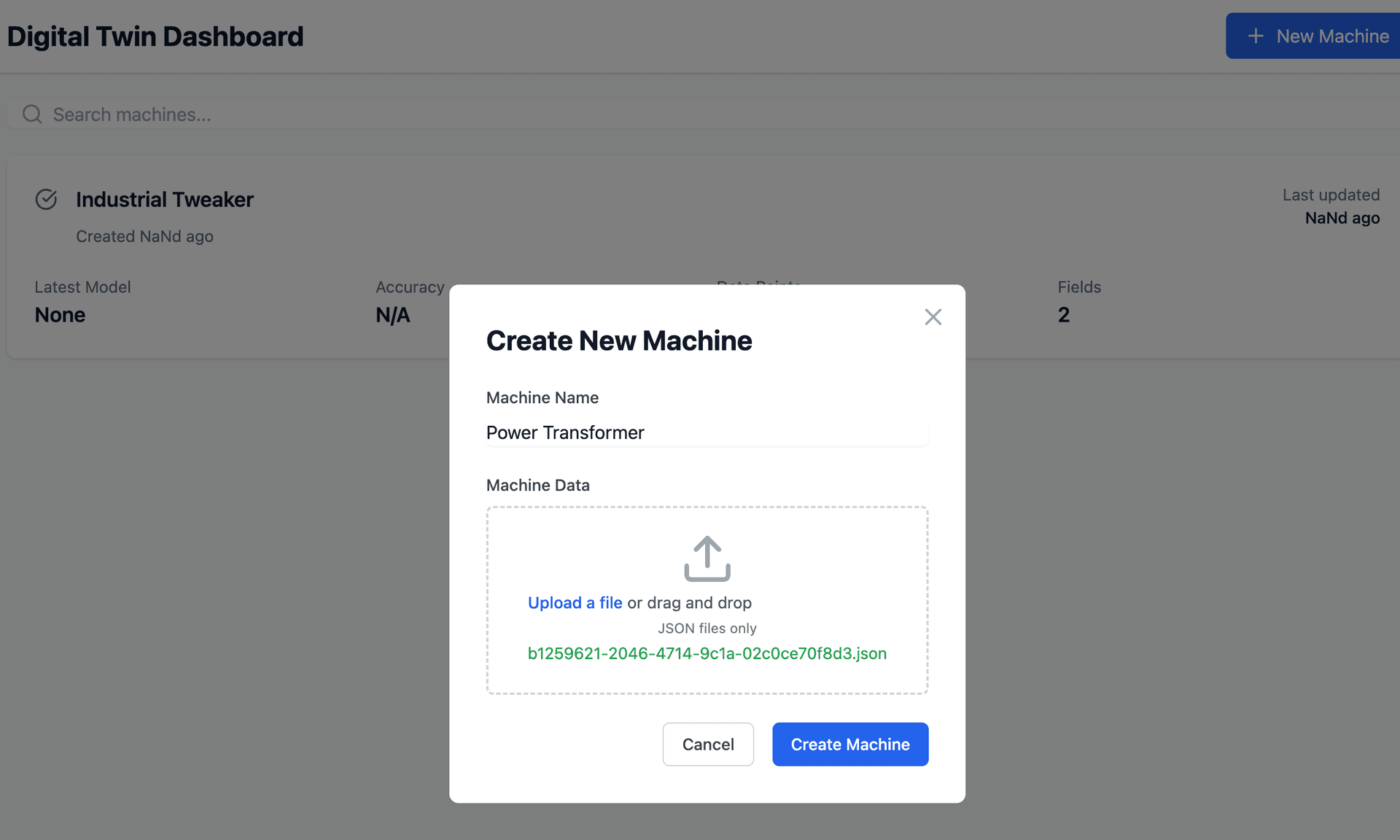

We developed ModelicaSim, a platform that leverages AI to automatically generate Modelica simulation models from historical machine data. The solution uses Claude 3.5 Sonnet to analyze time-series data from physical systems and generate accurate Modelica code that creates digital twins. The platform includes data visualization, automated model generation, and a dashboard to track multiple machines and their digital twins, making the entire process more efficient and accessible.

>Challenges

Accurate Modelica Code Generation

Creating an AI system that could generate accurate Modelica simulation code from raw machine data required sophisticated prompt engineering and iterative refinement.

Data Processing and Visualization

Handling diverse industrial machine data formats and creating meaningful visualizations to compare real data with simulated results.

>Approach

Full-Stack Architecture

We built a two-component system with a Flask backend for data processing, model generation, and Modelica simulation, and a Next.js frontend for user interaction and visualization.

AI-Powered Model Generation

We leveraged Claude 3.5 Sonnet to analyze time-series data and automatically generate Modelica code, with an iterative refinement process to improve accuracy.